Widely used in the mining industry, the Vertical Composite Crusher crushes material via extreme centrifugal impact. The Vertical Composite Crusher is suitable for crushing feed material of medium hardness commonly found in the cement, chemical, electrical power, metallurgy, and other industrial sectors. Common feed materials are limestone, slag, coke, amongst other materials.

To put it simply, the Vertical Composite Crusher will suit companies that wish to crush materials with relatively lower ore hardness and require high hourly output. Limestone is not particular hard and the Vertical Composite Crusher and therefore, is best suited for this application.

Working Principle

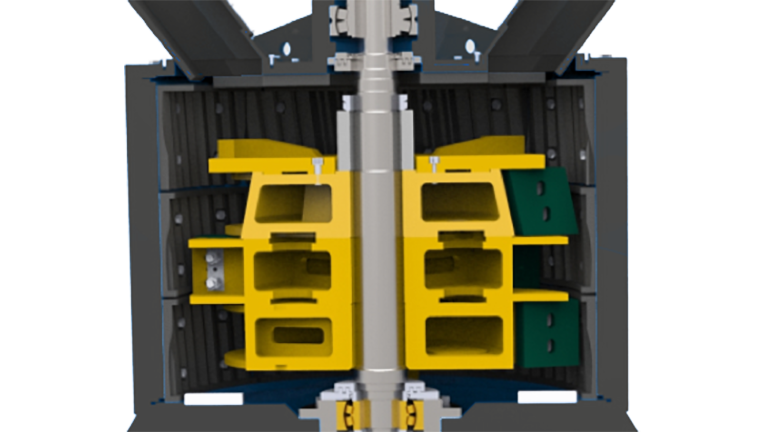

An optimised crushing chamber and multi-stage rotor design provides maximum yields for required high quality end products.

The high speed rotor is driven counter-clockwise by an electrical motor via a V-belt. Feed material entering the crushing chamber from the top is immediately met with the high centrifugal force created by the high velocity spinning multi-stage rotor.

This material is then continuously impacted multiple times by the rotor hammers and against the crusher body’s impact liners as it passes downwards through the crusher body. The space cavity progressively becomes smaller towards the bottom of the crusher.

The discharged product is cubically shaped and finely sized, with 70 – 90% equal or less than 3mm. This highly efficient method of crushing has relatively low power requirements and results in reduced operational cost per ton of production.

Key Characteristics

Wide Range of Applications

Vertical Composite Crushers are widely used in mining, smelting, building materials, chemistry, water conservancy, and many other industries. They are suitable for crushing all materials with a compressive strength of less than 250MPa.

Low Cost and Low Energy Consumption

The vertical composite crusher integrates coarse crushing and shaping functions when crushing materials. The feed material does not need to undergo additional crushing machinery in order to achieve saleable end products. This greatly reduces the overall cost of equipment at a crushing plant as well as energy consumption.

Safe and Reliable Operation

With a large diameter main shaft and heavy-duty main frame, the Vertical Composite Crusher is sturdy and durable. Long-term operation is reliable as it comes standard with an automatic control system with safety protection.

Compact Structure and Design

The PFL Vertical Composite Crusher is easy to install and operate. During long-term usage, subsequent maintenance will bring about time-saving and labour-saving benefits.

Everything is very open with a clear description of the issues. It was really informative. Your website is useful. Thanks for sharing!